Our offering

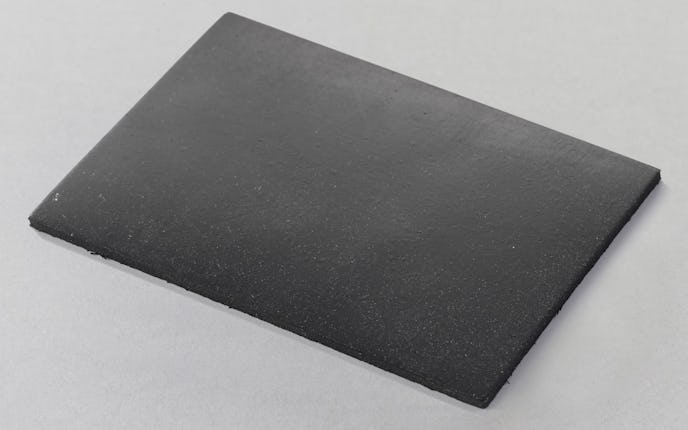

- High-performance quality seals and moulded parts out of NBR according to DIN-Norm and Siemens Norm SN 53145-1

- Individual cuts using our ultramodern 3D purewater cutting machinery

- Many resistances

- Plate or rolled goods

- Seamless XXL format

- From quantity 1 up to series production

- High Quality