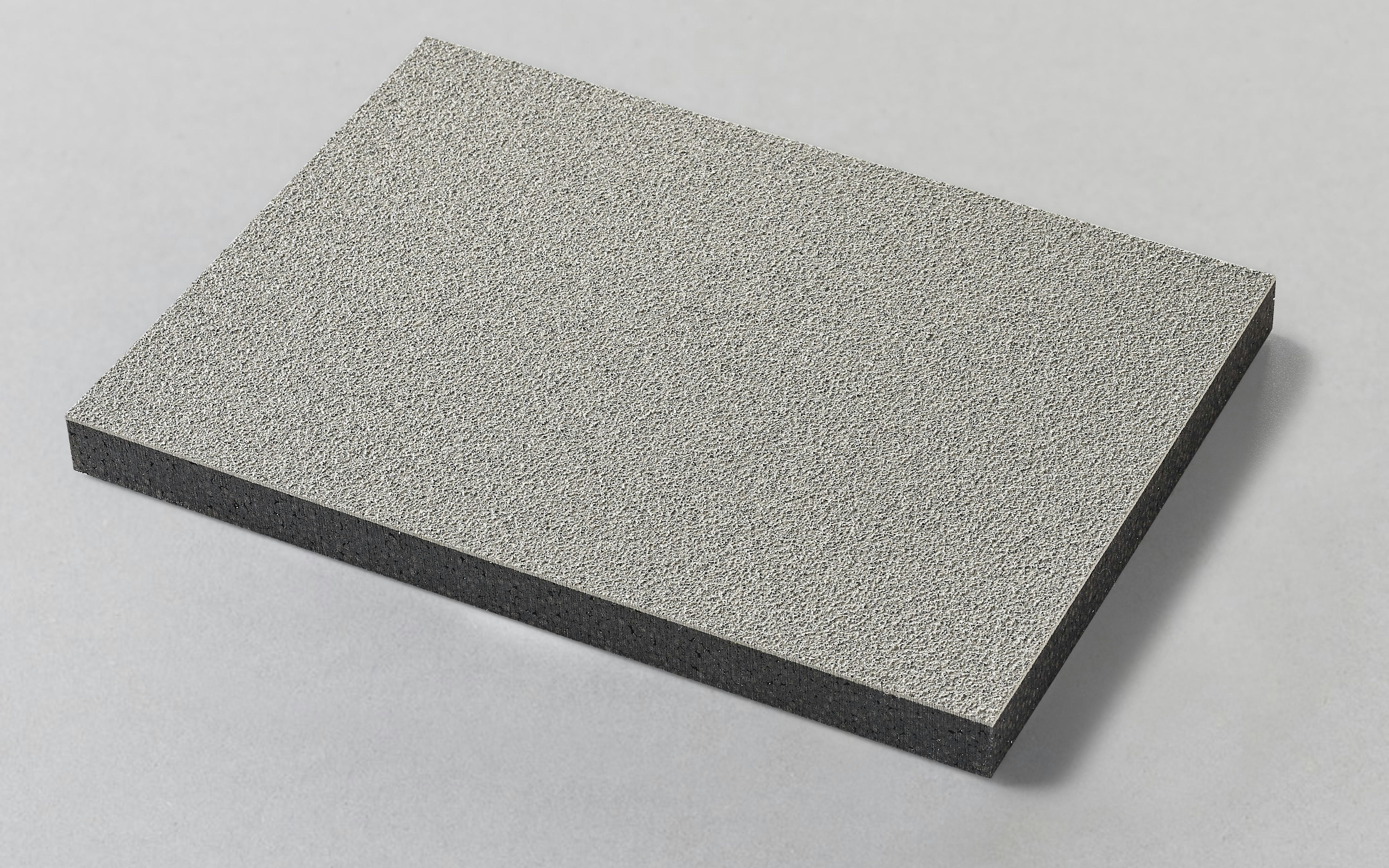

EPP moulded parts

EPP boards and moulded parts in various designs, individually cut-to-size and assembled: best for heat insulation and sound absorption (sound protection) or also as high-quality packaging.

Examples of use

- Individual dimensions and customisations of EPP boards and moulded parts

- Tool-specific moulded parts

- Assembly

- Various densities available

- Closed-cell expanded polypropylene foam (EPP)

- Customized material developments

- Various thicknesses, colours and surface laminations

- Recyclable material

- Short and on-time delivery

- Qualified advice