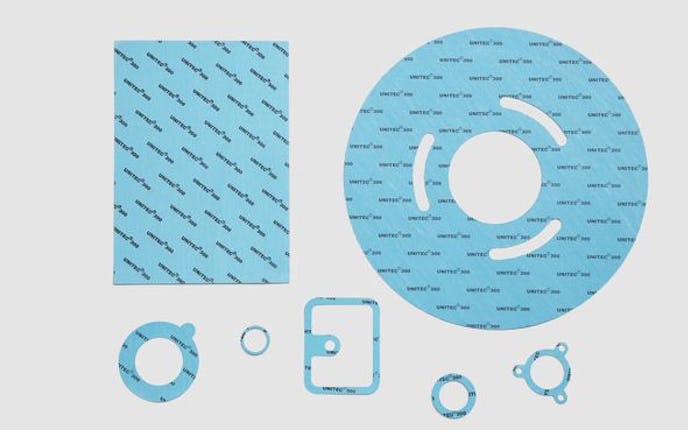

Our offering

- Flange seals from different materials and in most diverse sizes

- Different shapes, ex. O-shaped 2-D seals

- Ready-to-install and adhesive for the simple and quick mounting

- Individual cut, including the fitting holes

- Many resistances

- From quantity 1 up to series production

- High Quality