Our offering

- Low-wear quality seals and moulded parts out of EPDM

- According to the European DIN standard

- Many resistances

- Plate or rolled goods

- Seamless XXL format

- Individual cut

- From quantity 1 up to series production

- High Quality

Our available EPDM-materials

A-KJ 50-00

Technical Data Sheet

Qualities

- EPDM quality, peroxide cured

- makrolon and prexiglas resistant

- conform with FDA 21§177.2600

- compliant with the French Drinking water approval (CLP certificate)

- complies with VW 2.8.1 G65 (at 130 °C) and DBL 5556.30

- short time temperature resistant to 150 °C

Delivery forms

| The material is available in rolls. | |

| Length | on request |

| Width | 3,200 mm |

| Thickness | on request |

| Other sizes and cut-to-size pieces upon request. |

A-KL 65-00

Technical Data Sheet

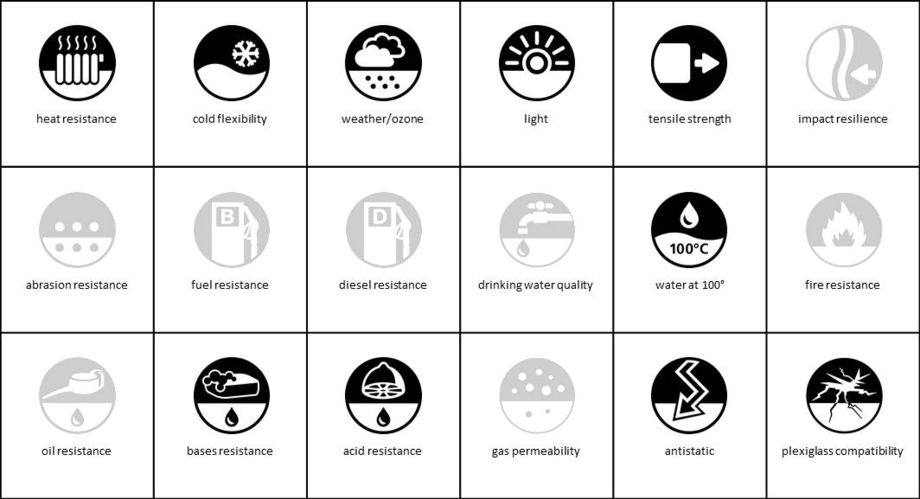

Resistances

Qualities

- EPDM quality, peroxide cured

- makrolon and prexiglas resistant

- conform with FDA 21§177.2600

- compliant with the French Drinking water approval (CLP certificate)

- complies with VW 2.8.1 G65 (at 130 °C) and DBL 5556.30

- short time temperature resistant to 150 °C

Delivery forms

| The material is available in rolls. | |

| Length | on request |

| Width | 3,200 mm |

| Thickness | on request |

| Other sizes and cut-to-size pieces upon request. |

EPDM 65 peroxid

Technical Data Sheet

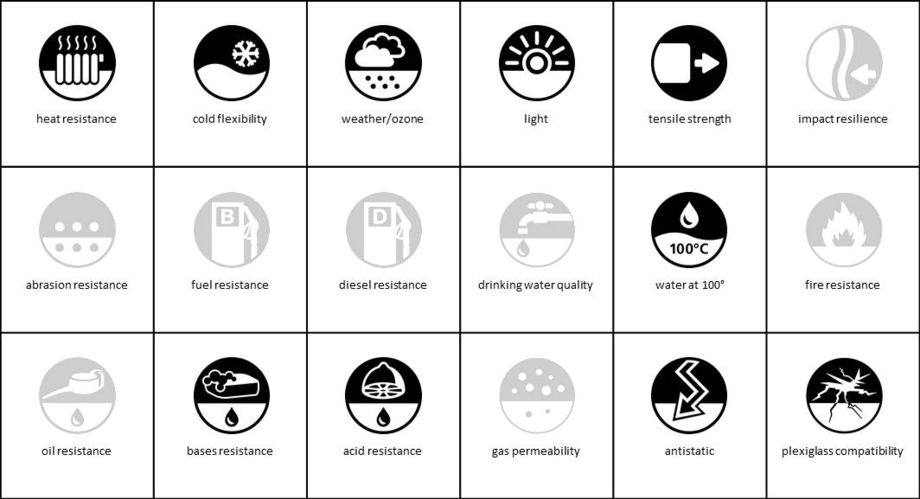

Resistances

Qualities

- EPDM quality, peroxide cured

- makrolon and prexiglas resistant

- conform with FDA 21§177.2600

- compliant with the French Drinking water approval (CLP certificate)

- complies with VW 2.8.1 G65 (at 130 °C) and DBL 5556.30

- short time temperature resistant to 150 °C

Delivery forms

| The material is available in rolls. | |

| Length | on request |

| Width | 3,200 mm |

| Thickness | on request |

| Other sizes and cut-to-size pieces upon request. |

A-KT 70-00

Technical Data Sheet

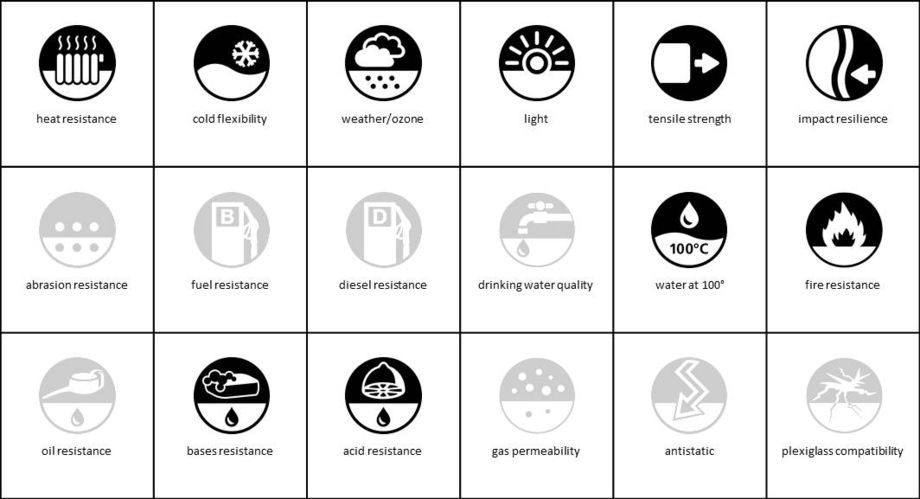

Resistances

Qualities

- EPDM material for drinking water applications (ethylene propylene diene monomer rubber)

- Certification of KTW and DVGW W270

- WRAS certificated

- PAK content in accordance with Kat. 2 of ZEK 01 2-08)

- Peroxide cured

Delivery forms

| The material is available in rolls. | |||

| Length | 1,000 mm | 5,000 mm | 10,000 mm |

| Width | 1,400 mm | ||

| Thickness | 2 mm | 3 mm | 5 mm |

| Other sizes and cut-to-size pieces upon request. |

A-KX 55-15

Technical Data Sheet

Resistances

Qualities

- Insulating blanket EPDM-material (ethylene propylene diene monomer rubber)

- Certificated for electrical insulating blankets according DIN EN 61112 A,Z

- Salmon according to RAL 3022

- PAK content in accordance with GS-regulations ZEK 01.2-08

- Nitrosamine free and halogene-free

Delivery forms

| The material is available in rolls. | |||

| Length | 1,000 mm | 5,000 mm | 10,000 mm |

| Width | 1,000 mm | marked with 2 Vulkanetten® | |

| 1,200 mm | marked with 3 Vulkanetten® | ||

| Thickness | 1 mm | 1.6 mm | |

| Other sizes and cut-to-size pieces upon request. |